Velocys’ Fischer-Tropsch reactor and FT catalyst technologies combine to overcome temperature and pressure challenges associated with the Fischer-Tropsch process. Our microchannel FT reactors and Oxford-engineered catalysts enable safe SAF production at commercial scale and at a reduced overall cost. This is advanced system is now avaliable for licensing through our microFTL™ Technology license packages.

Velocys produces the world’s most compact Fischer-Tropsch reactor for the synthesis of hydrocarbons and allows the production of advanced biofuels from large, sustainable carbon sources such as household waste and forest residues.

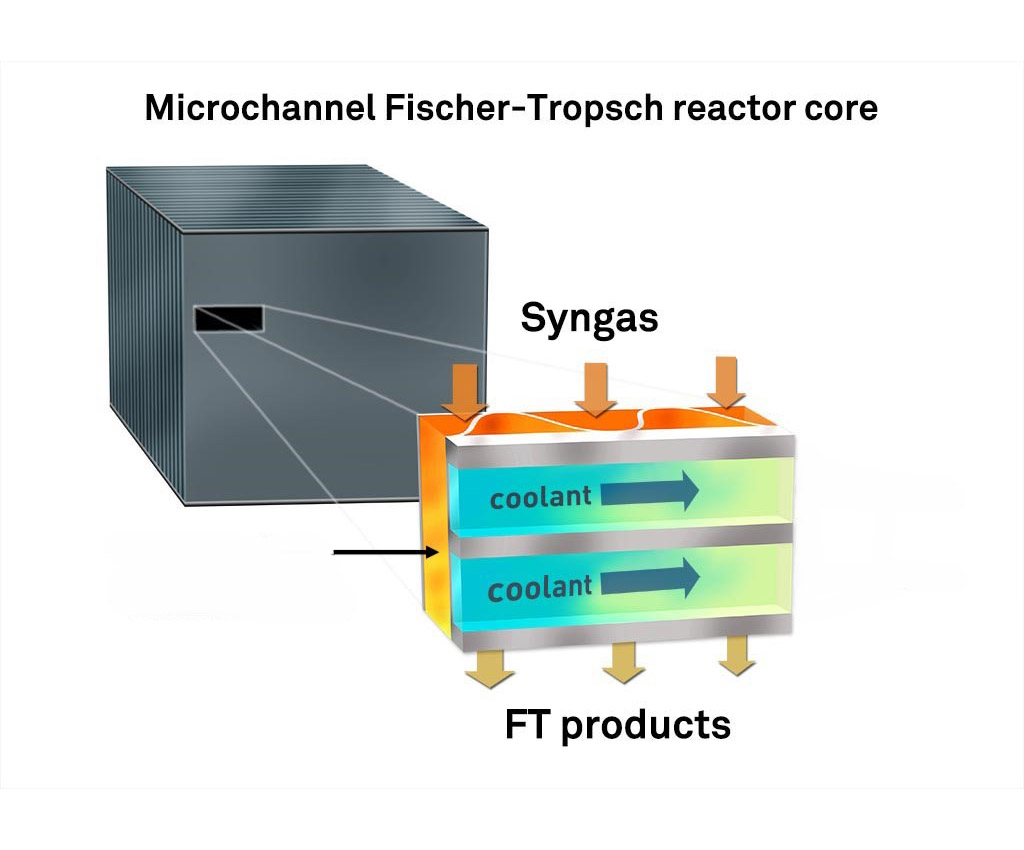

Velocys’ license offering combines microchannel FT reactors, Oxford-engineered highly active catalysts, and hard-earned FT process expertise in a full FT package. Our FT technology is modular, using standard reactor design proven at commercial scale. Microchannel reactors enable efficient heat transfer and control, supporting process stability with high selectivity for high-value sustainable fuel products. The proprietary FT catalyst complements the novel reactor architecture enabling an exceptional high volumetric productivity 6-10 times that of traditional FT technologies. The technology can achieve and maintain high per-pass (70%) and overall (up to 98%) CO conversion and has an excellent catalyst-wax separation performance, with no need for post-reactor solids removal.

These materials are not directed at, or accessible by, persons resident in the United States. If you are not permitted to view materials on this webpage or are in any doubt as to whether you are permitted to view these materials, please exit this webpage.

Viewing the materials you seek to access may not be lawful in certain jurisdictions. In other jurisdictions, only certain categories of person may be allowed to view such materials.

In particular, unless otherwise determined by the Company and permitted by applicable law and regulation, it is not intended, subject to certain exceptions, that any offering of the securities mentioned in such materials (the “securities”) by the Company would be made, or any documentation be sent, directly or indirectly, in or into Canada, United States, Australia, New Zealand, Japan or South Africa.

Subject to certain exceptions, the materials do not constitute or form a part of any offer or solicitation to purchase or subscribe for the securities in Canada, United States, Australia, New Zealand, Japan or South Africa or any jurisdiction or jurisdictions in which such offers or sales are unlawful prior to registration or qualification under the securities laws of any such jurisdiction. In particular, the securities referred to herein and on the pages that follow have not been and will not be registered under the United States Securities Act of 1933, as amended (the “Securities Act”), or with any securities regulatory authority of any state or other jurisdiction of the United States and may not be offered, sold, re-sold, taken up, pledged, delivered, distributed or otherwise transferred, directly or indirectly, in the United States except pursuant to an exemption from, or in a transaction not subject to, the registration requirements of the Securities Act and applicable state securities laws.

There will be no public offer of the securities in Canada, United States, Australia, New Zealand, Japan or South Africa. The securities may not be offered, sold, resold, taken up, exercised, renounced, transferred, delivered or distributed, directly or indirectly, through CREST or otherwise, in, Canada, United States, Australia, New Zealand, Japan or South Africa or to or for the benefit of any resident of, Canada, United States, Australia, New Zealand, Japan or South Africa, or any other jurisdiction if to do so would constitute a violation of the relevant laws of, or require registration thereof in, such jurisdiction.

Making press announcements and other materials available in electronic format does not constitute an offer to sell or the solicitation of an offer to buy any securities in the Company. Further it does not constitute a recommendation by the Company or any other party to sell or buy securities in the Company.

While the Company has taken reasonable care to ensure that the information on this website (other than information accessed by hyperlink) is accurate at the time of last revision of the website, the Company accepts no liability for the accuracy or completeness or use of, nor any liability to update, the information contained on this website. It should not be construed as the giving of advice or the making of a recommendation and should not be relied on as the basis for any decision or action. In particular, actual results and developments may be materially different from any forecast, forward-looking statement, opinion or expectation expressed on this website.

The information on the pages that follow may contain forward-looking statements. Any statement other than a statement of historical fact is a forward-looking statement. Such forward-looking statements involve known and unknown risks, uncertainties and other factors, which may cause actual results to differ materially from those express or implied by any forward-looking statement. The Company does not undertake any obligation to update or revise any forward-looking statements, whether as a result of new information, future events or otherwise. You should not place undue reliance on any forward-looking statement, which speaks only as of the date of its issuance.

By clicking on the “I agree” button, you represent, warrant, certify and agree that (1) you are not located in the United States, (2) you are permitted under applicable laws and regulations to receive the information contained in the pages that follow, (3) you have read and understood the disclaimer set out above and agree to be bound by its terms, (4) understand that it may affect your rights and (5) agree that you will not transmit or otherwise send any information contained in this website to any person in the United States or to publications with a general circulation in the United States.”

The information in this section of the website is, therefore, not available to persons located in your country of residence. We regret that we cannot provide you with the requested information. We apologise for any inconvenience this may cause. Please exit this webpage.