Learn how Fischer-Tropsch technology works, why microchannel FT reactors matter, and how Velocys leads in SAF, e-fuels, and waste-to-fuel solutions.

The FT process is a chemical reaction that converts synthesis gas (a mixture of carbon monoxide and hydrogen, often called syngas) into liquid hydrocarbons such as jet fuel, diesel, naphtha, and waxes. The process uses a catalyst (typically iron or cobalt-based) to facilitate the conversion at elevated temperatures and pressures. FT synthesis plays a foundational role in the production of synthetic fuels and chemicals from non-petroleum feedstocks like natural gas, biomass, biogas, municipal solid waste, or captured CO2.

FT technology requires a high-quality syngas (which is a gaseous stream of hydrogen and carbon monoxide). This syngas stream can be produced from a wide range of feedstocks including:

The composition of the syngas and the ratio of carbon monoxide to hydrogen play a crucial role in FT synthesis. Syngas production and clean-up technologies are critical for high FT yield.

Note: Pyrolysis gas streams are not suitable for FT conversion.

The two required feedstocks for FT synthesis are hydrogen (H2) and carbon monoxide (CO). This mixture is commonly called syngas. The FT process requires a ratio of around 2.1 H2 molecules to every CO molecule (syngas ratio of ~2.1:1). However, each FT technology has been optimised for different ratios to suit the conversion and selectivity specific to their catalyst and reactor configuration. A feedstock range of 1.7 – 2.1 is typical.

The level of inert gases (including methane, carbon dioxide, and nitrogen) that an FT system can manage is also technology-specific. What the industry calls “poisons” (sulphur compounds/reactive nitrogen/carbonyls) are significantly problematic for cobalt-based FT catalysts. Other byproducts like CO2, CH4, H2O, and N2) can affect performance (by reducing the syngas partial pressure, for example) but do not degrade the catalyst directly. The percentage of inerts vs. the percentage of syngas is a controlling factor in catalyst performance.

The main sustainable fuels derived from FT synthesis are SAF, diesel, and naphtha. Small amounts of propane and butane (LPGs) can be co-produced with these primary fuel products. Kerosene can also be produced, as this is a cruder form of synthetic paraffinic kerosene (SPK).

Sustainable propane and butane (LPGs) are a small by-product of FT synthesis, but they are not typical target molecules. Other sustainable fuels like hydrogen, fuel oil, synthetic natural gas (SNG), ethanol, and HEFA-based products do not use FT synthesis.

Traditional Fischer-Tropsch reactors (slurry bed and conventional tubular reactors) face challenges such as:

Modern advancements, such as microchannel reactor design, aim to address these issues.

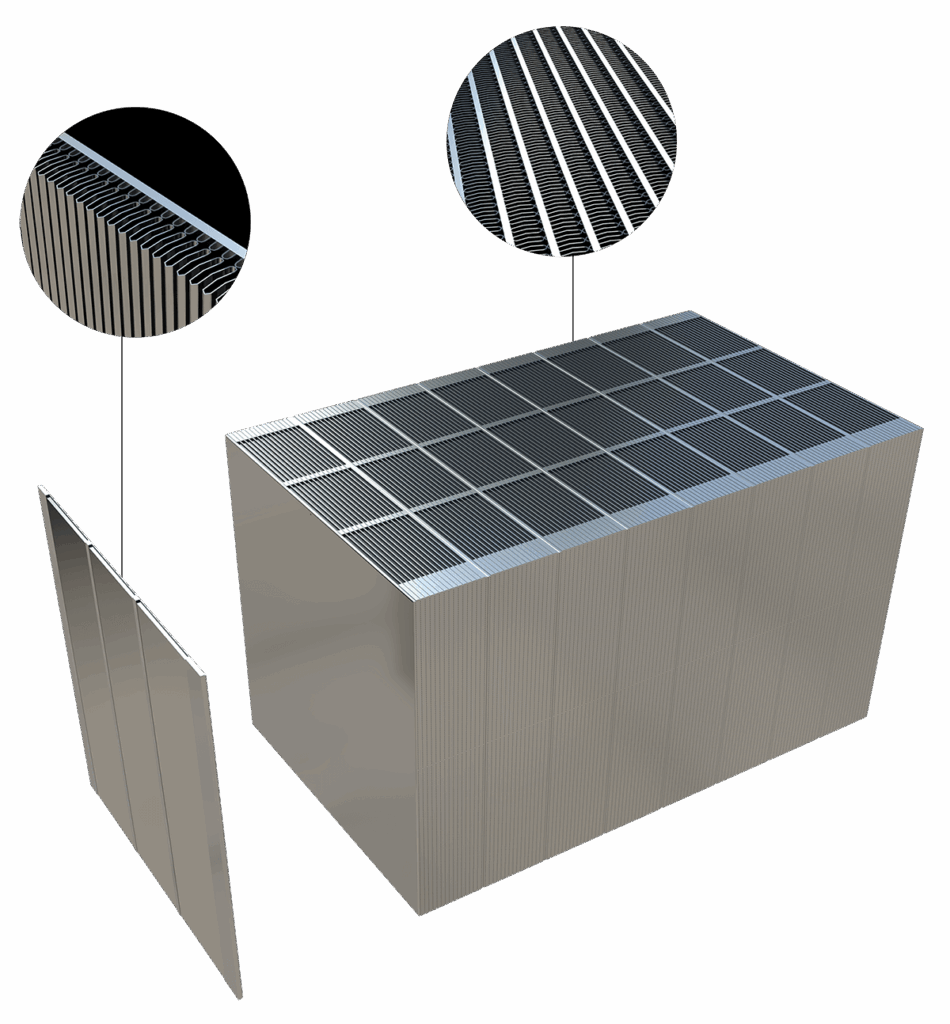

A microchannel reactor contains thousands of small, parallel flow channels—each typically less than 1 mm in diameter—embedded within a metal block. These microchannels significantly enhance heat and mass transfer, which is critical in controlling the highly exothermic FT reaction.

FT microchannel compared to tubular fixed-bed FT reactors

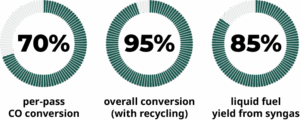

Note: Velocys microchannel reactors and Oxford-engineered catalysts can achieve up to 98% conversion with recycling.

FT microchannel compared to slurry bubble column/ slurry-bed FT reactors

Note: Velocys microchannel reactors and Oxford-engineered FT catalysts can achieve up to 98% conversion rates

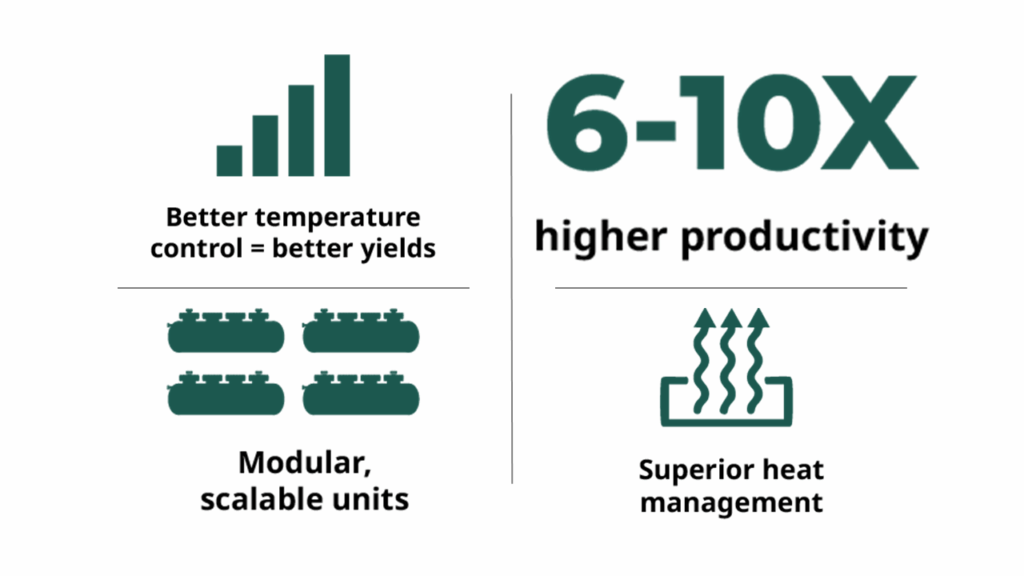

Microchannel reactors offer superior heat control, reducing thermal gradients and hot spots, which prevents catalyst degradation and maintains optimal reaction conditions. This improves selectivity for C5+ hydrocarbons (e.g., jet fuel range) and reduces the formation of low-value byproducts. Note that final improved jet yields are directly related to crude upgrading, which occurs after FT synthesis.

Microchannel FT reactors like those developed by Velocys provide optimal reaction conditions across the operational life of the plant. This translates into:

Instead of scaling a single large reactor, microchannel systems scale through replication (numbering up). This modular approach:

Microchannel reactors are typically standardized units manufactured offsite and assembled into modules. This standardization enables repeatability, quality control, and faster deployment, especially important in SAF and e-fuels projects aiming for commercial-scale rollouts.

CO conversion refers to the percentage of carbon monoxide in syngas that is converted into hydrocarbons during the FT process. It is typically expressed in two ways:

High CO conversion improves reactor efficiency, reduces recycle loop requirements, and boosts overall fuel yield. It also means better utilization of feedstock, which is critical in commercial operations with cost or carbon intensity constraints.

Catalyst formulation directly affects how selectively CO and H2 are transformed into target products. High-performing catalysts:

Temperature, pressure, and reactor geometry determine the range of hydrocarbons produced. Higher temperatures often increase light gas formation, while optimized temperature control (as enabled by microchannels) enhances selectivity for the desired longer-chain hydrocarbons.

Fuel yields depend on feedstock, catalyst, and reactor design, but advanced microchannel FT systems can deliver up to 85% liquid fuel yield from syngas with optimized integration and gas recycling.

Velocys is a technology company that develops and licenses microchannel Fischer-Tropsch reactor systems and catalysts for the production of low-carbon synthetic fuels. They offer fully constructed FT modules, standard product packages, and fit-for-purpose designs. The technology has been demonstrated at commercial scale and is used in projects targeting SAF and renewable diesel, both biofuels and e-fuels.

Velocys reactors use microchannel architecture with Oxford-engineered high-performance catalysts to enable high productivity, excellent heat management, and modular scale-up.

They offer:

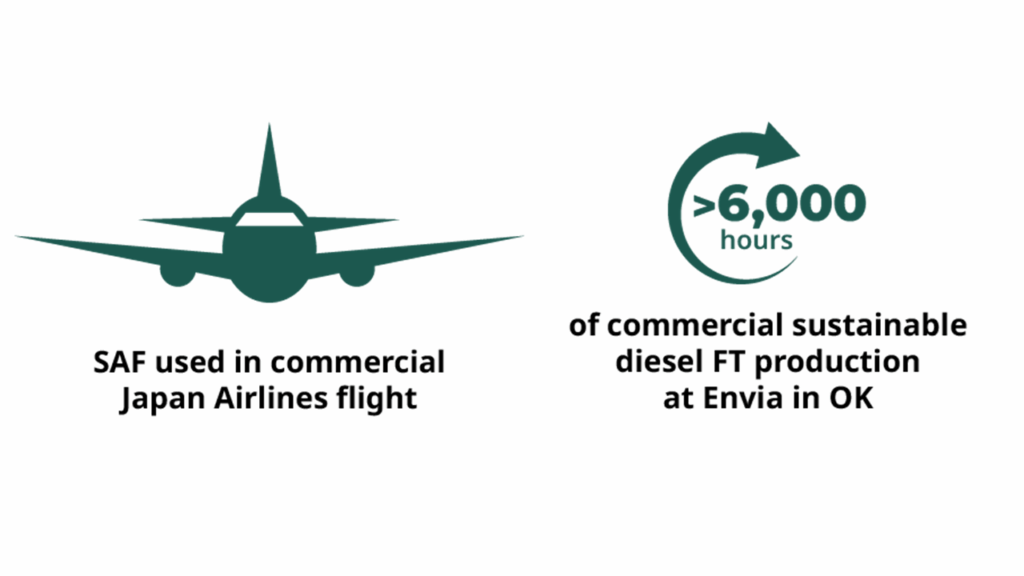

Key Fischer Tropsch technology deployments include:

Velocys’ proprietary catalyst was engineered at Oxford for high activity and selectivity. It supports stable operation and high fuel yields without requiring complex reactor solids removal.

Yes. Velocys technology follows the ASTM D7566-certified FT-SPK pathway, allowing the SAF it produces to be blended into conventional jet fuel up to 50%.

Velocys previously operated two production facilities in the US, the largest of which was a 52,000 sq ft reactor assembly and catalyst production plant in Columbus, Ohio. Given market and customer preferences, Velocys now oversees manufacturing and assembly at various geographies around the world near project locations. This strategy boosts local content, reduces supply chain uncertainty, and helps derisk investment for customers.

FT technology is primarily used to convert syngas into liquid hydrocarbons for:

The BtL process typically includes:

PtL systems use renewable electricity to generate hydrogen (via electrolysis) and combine it with CO2 (captured from air or point sources and then converted into CO) to create syngas. This syngas feeds into FT reactors to produce synthetic hydrocarbons, forming the backbone of e-fuels.

Yes. Especially with microchannel reactor systems, FT plants can be modularized and downsized for:

Products from FT synthesis often undergo upgrading steps such as:

The CI of FT-derived fuels depends on feedstock, energy input, and process configuration. Advanced FT systems using biomass or waste feedstocks can achieve very low, or even negative, CI scores. For example, Velocys’ AltAlto project reported an expected CI score of -50 gCO2e/MJ.

By integrating carbon-neutral or carbon-negative feedstocks (e.g., biomass, biogas, captured CO2), FT plants can displace fossil fuel use and actively reduce atmospheric carbon. Combined with renewable power, FT enables power-to-liquid systems that close the carbon loop.

FT plants have historically been capital intensive, but microchannel and modular reactor designs reduce upfront costs. Operating costs are competitive, especially where low-cost feedstocks (e.g., waste, biogas, biomass) or carbon credits (LCFS, 45Q) apply.

Scalability is increasingly viable due to:

Fischer-Tropsch technology—especially in microchannel form—is proving to be a critical platform for the production of sustainable, drop-in fuels from diverse feedstocks. From large-scale SAF projects to decentralized e-fuel hubs, FT synthesis offers technical maturity, commercial viability, and a clear path toward net-zero emissions.

Note on Policy and Regulation: Regulations around SAF, e-fuels, and low-carbon fuels vary by region and change frequently. For the latest updates, refer to:

Contact us to learn more about license opportunities for Velocys’ microchannel FT reactor technology.